In modern warehouses, distribution centers, and manufacturing plants, the efficiency of product movement is a critical factor in productivity. Sortcon offers a complete range of conveyor solutions designed to handle every stage of material flow — from loading and unloading to sorting, merging, and diverting. By integrating innovative technologies such as telescopic conveyors, curved belt conveyors, and belt driven roller conveyors, we ensure that goods travel smoothly, accurately, and at the right speed to their destination.

Streamlined Loading and Unloading with Telescopic Conveyors

The telescopic conveyor is an essential tool for improving loading and unloading operations. Extending directly into trailers or containers, it minimizes manual handling, reduces operational time, and increases worker safety. Whether for inbound goods or outbound shipments, this system optimizes dock efficiency while maintaining consistent throughput.

Efficient Merging and Product Flow Control

When multiple product lines need to be combined into a single stream, merge conveyors and product merging conveyors provide precise control over timing and alignment. Merging conveyors can handle varying speeds and product sizes, ensuring smooth integration into the main conveyor line without bottlenecks.

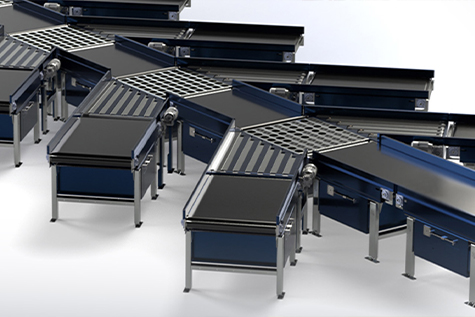

Handling Complex Routes with Curved Conveyors

A curved belt conveyor or curve conveyor enables product movement around corners without disrupting orientation or speed. For more demanding applications, a curved conveyor maintains a continuous flow even in tight spaces, making it a perfect solution for maximizing facility layouts.

High-Performance Belt Driven Roller Systems

In operations where controlled movement and accumulation are needed, the belt driven roller conveyor or belt driven live roller conveyor offers excellent performance. These systems allow for smooth transport of varying loads while reducing noise and wear, making them ideal for both light and heavy-duty applications.

Smart Product Sorting and Diverting

Sorting is a crucial part of order fulfillment and distribution. A diverting conveyor and lane diverting conveyor direct products to specific destinations with accuracy. For more advanced sorting requirements, roller conveyor diverters quickly redirect items without stopping the main conveyor flow, increasing throughput and efficiency.

Precision with Weighing & Scanning

Integrated weighing & scanning systems ensure that each product is correctly identified, weighed, and tracked during transit. This step enhances inventory accuracy, improves order fulfillment, and supports data-driven logistics operations.

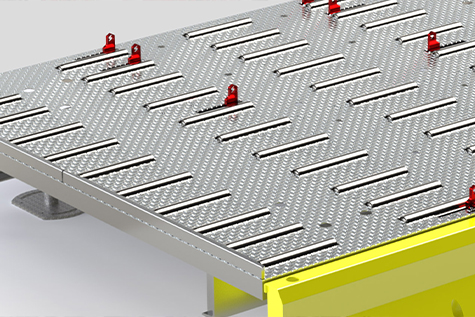

Specialized Platforms for Smooth Transfer

For areas where items need to change direction or move between systems, a castor deck offers effortless manual maneuverability, while a swivel wheel sorter efficiently handles multiple destination points. In manual handling zones, a manual conveyor or popup conveyor can be implemented for flexible, on-demand product movement.

Why Choose Sortcon Conveyor Solutions?

At Sortcon, our expertise lies in designing integrated systems that combine the right mix of conveyors, sorters, and accessories for your operational needs. Whether it’s a product merging conveyor feeding into a curve conveyor, or a lane diverting conveyor linked to a telescopic conveyor, every element is built for durability, precision, and scalability.

By adopting Sortcon’s advanced conveyor solutions, businesses can reduce handling costs, improve operational safety, and maximize throughput — ensuring they stay competitive in today’s fast-paced supply chain environment.