Conveyor X-Ray Inspection Machines

Sortcon

Conveyor X-ray inspection systems are an essential tool for ensuring the safety and integrity of goods in transit, providing detailed scans for a range of industries including logistics, manufacturing, and security. With the integration of X-ray conveyor belts, these systems allow for the efficient inspection of packages and products moving along a conveyor line, ensuring that potential threats or contaminants are detected without disrupting the flow of operations.

A conveyor belt X-ray machine utilizes advanced imaging technology to scan items as they pass through the system, allowing for quick and precise identification of any irregularities. This ensures that products are thoroughly inspected before reaching their final destination, improving overall security. The system can be tailored to meet the specific needs of a facility, with options for different conveyor sizes and scanning capabilities.

For enhanced detection, conveyor X-ray scanners provide high-resolution images that allow security personnel to identify even the smallest hidden threats. These systems offer a high level of accuracy and reliability, reducing the likelihood of undetected issues. A conveyor X-ray inspection system not only streamlines security processes but also ensures a high level of operational efficiency by allowing for continuous inspection without slowing down the conveyor flow. This makes it an indispensable solution for businesses seeking to maintain safety while optimizing throughput.

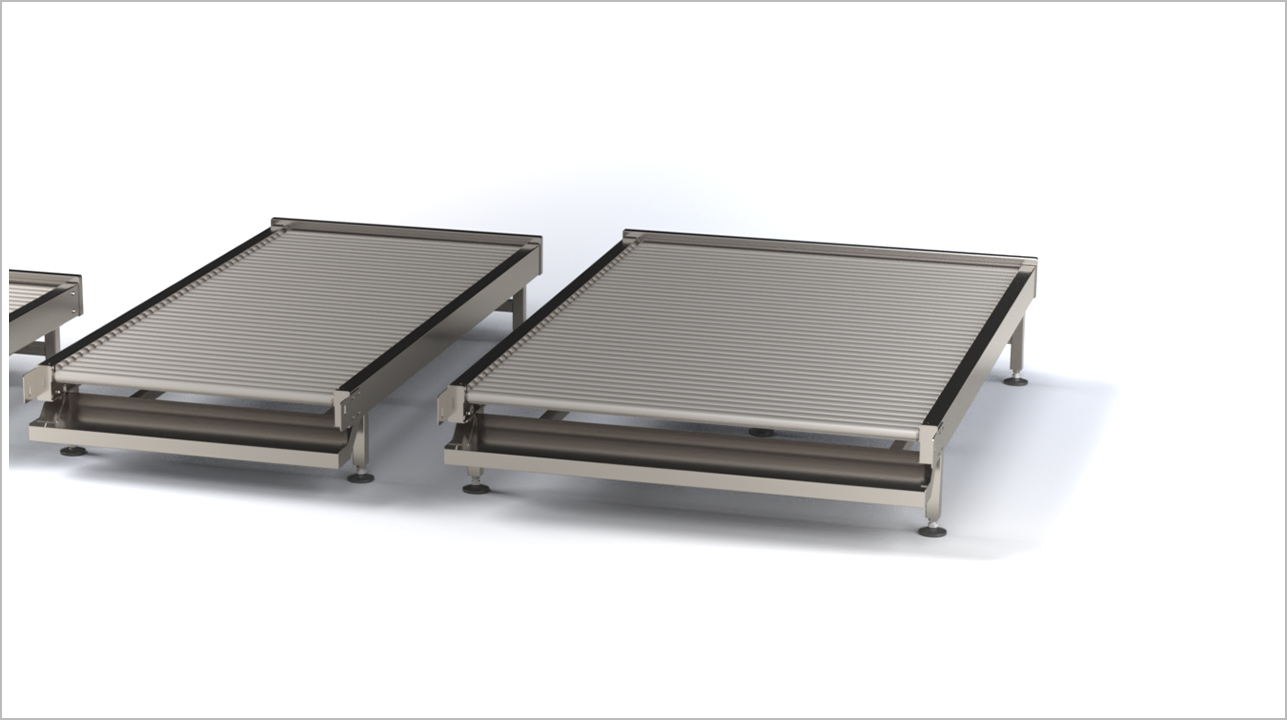

X-Ray Connector: Enhancing safety and precision for items passing through.

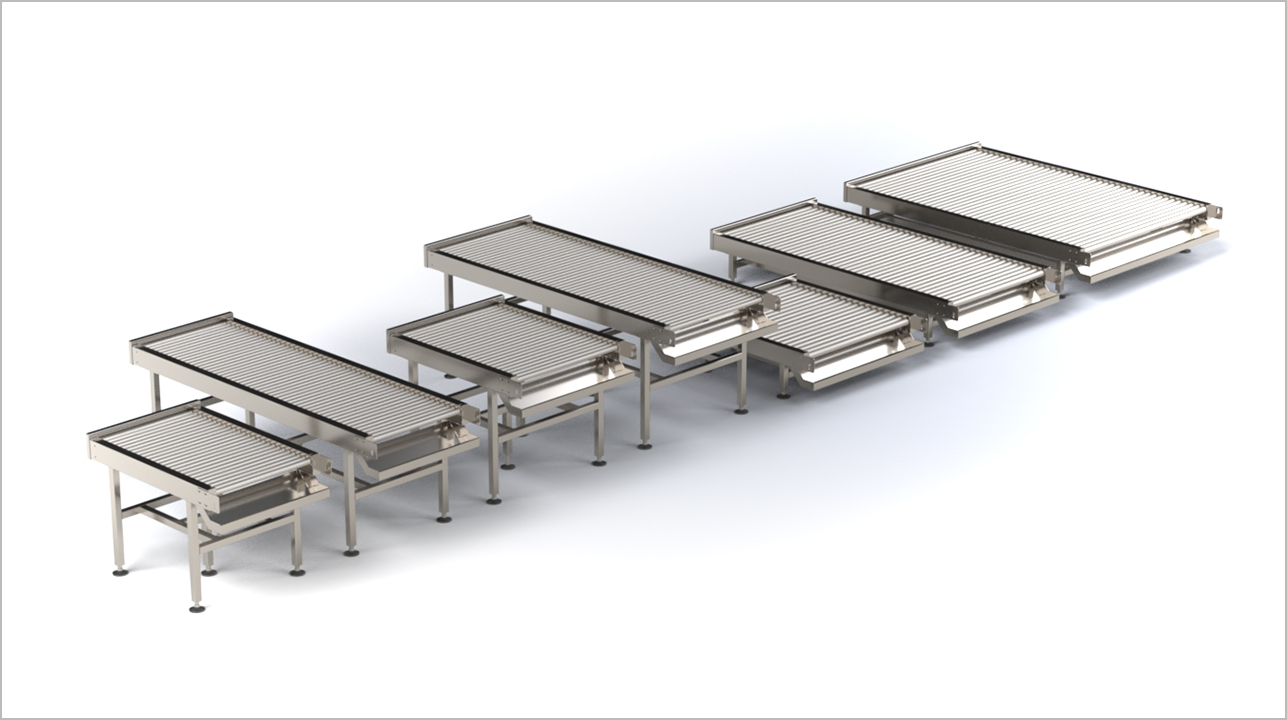

Conveyor Connector: Ensuring seamless transitions between conveyor sections.

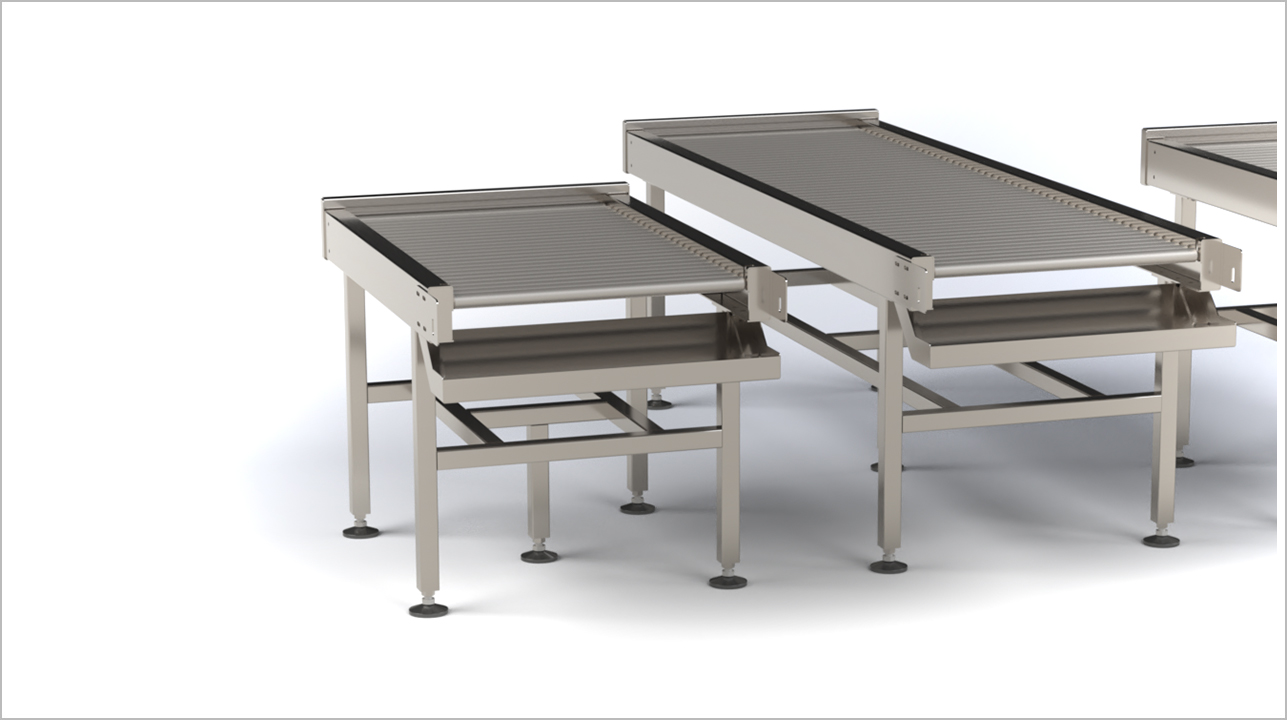

Dropped Item Basket: Minimizing losses by safely collecting any items that fall off.

Anti-Shake Leg: Providing stability and reducing vibration for smoother operations.