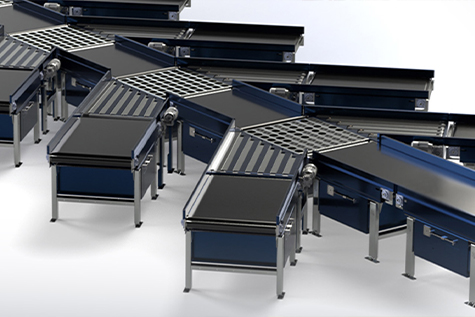

In today’s fast-paced manufacturing and logistics environments, efficient material handling is crucial for maintaining productivity and reducing operational costs. At Sortcon, we provide one of the most effective solutions for optimizing workflows: roller conveyor systems. These systems come in various configurations, each designed to meet specific operational needs. Let’s explore the different types of roller conveyors offered by Sortcon and how they can enhance your material handling processes.

Understanding Sortcon's Roller Conveyor Systems

At the heart of many industrial applications is the roller conveyor. Sortcon’s systems utilize a series of rollers mounted on frames to move items along a production line or through a distribution center. Among the most popular configurations are gravity roller conveyor systems, which rely on gravity to transport items down an incline. These systems are ideal for applications where products need to be moved from one level to another with minimal energy expenditure.

On the other hand, Sortcon’s powered roller conveyors use motors to drive the rollers, providing more control over the movement of goods. This makes them particularly useful for handling heavier loads or items that need to be transported over longer distances without the assistance of gravity.

The Versatility of Gravity Roller Conveyors

Sortcon’s gravity roller conveyors are designed to handle a wide variety of products, from boxes to pallets. They can be easily integrated into existing production lines or distribution systems. For businesses looking for flexibility, our expandable roller conveyors offer an excellent solution. These systems can be adjusted in length and configuration, making them perfect for temporary setups or changing workflows.

For situations that require more control, Sortcon’s motorized roller conveyors provide an efficient means of moving products without manual intervention. With features like variable speed control and zone separation, these systems can significantly improve operational efficiency while reducing labor costs.

The Role of Conveyor Rolls

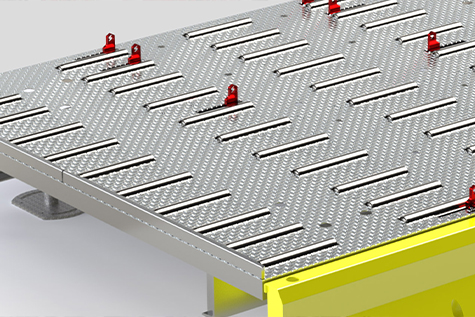

Conveyor rolls are essential components of any roller conveyor system, providing the necessary support and movement for the materials being transported. Sortcon ensures that high-quality conveyor rolls are used to guarantee smooth operation and reduce wear and tear on the system. Regular maintenance and inspection of these rolls can prevent costly downtimes and enhance the lifespan of your conveyor system.

Combining Functions with Roller Belt Conveyors

In addition to traditional roller conveyors, Sortcon offers roller belt conveyors that provide another layer of versatility. These systems combine rollers with a belt, allowing for the transport of items that require additional support or stabilization. This hybrid approach can be especially beneficial when handling delicate products or those with irregular shapes.

Whether you’re considering a rolling conveyor for lightweight materials or a heavy-duty powered roller conveyor for demanding applications, understanding the different types of roller conveyor systems offered by Sortcon is key to optimizing your material handling operations. By investing in the right conveyor solutions, businesses can enhance efficiency, reduce costs, and stay competitive in today’s dynamic market. Explore the various options available at Sortcon and discover how our roller conveyor systems can transform your workflow.