In today’s fast-paced industrial environments, businesses are continuously looking for cost-effective and flexible material handling solutions. Manual conveyor systems have emerged as a practical choice for companies aiming to streamline operations without relying on complex automation.

Why Choose a Manual Conveyor Belt?

A manual conveyor belt offers simplicity and control. Unlike automated systems, manual options allow operators to manage the pace of material movement, which is ideal for delicate sorting tasks or workflows with variable processing speeds. Whether you're working in packaging, logistics, or warehousing, a manual belt conveyor can adapt easily to your needs.

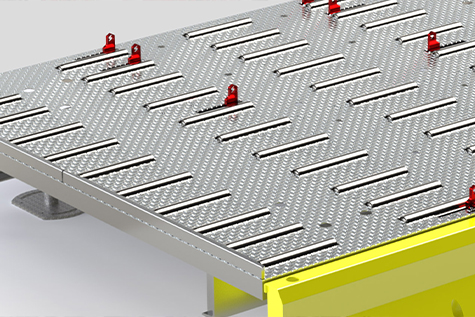

The Versatility of Manual Sorting Conveyor Systems

Manual sorting conveyor systems are especially useful in operations where hands-on management of goods is crucial. These systems provide workers with the ability to sort, inspect, or redirect items with precision. Thanks to their ergonomic design and smooth handling, they improve productivity while reducing physical strain.

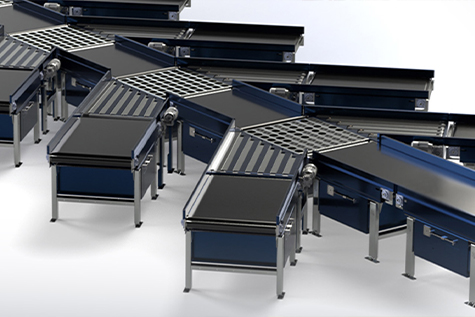

Manual Roller Conveyor Systems: Built for Customization

One of the most flexible options available is the manual roller conveyor systems. These systems feature rollers that enable effortless movement of goods across different stations. What makes them stand out is their adjustable length and configuration, which ensures a perfect fit for any production floor or storage facility.

Conveyor Belt Manual Handling for Operational Simplicity

For companies seeking reliability without the high maintenance of automated systems, conveyor belt manual solutions are the answer. They are easy to install, simple to operate, and require minimal training. Plus, their manual conveyor structure allows them to be easily relocated when workflows change, offering unmatched adaptability.

Long-Term Value and Efficiency

Choosing a manual conveyor belt setup doesn’t mean compromising on performance. In fact, the short production period, low operational costs, and reduced maintenance needs make manual sorting conveyor systems a smart investment for long-term efficiency.

Conclusion

If your business values operational control, flexibility, and cost savings, investing in manual conveyor systems—whether a manual belt conveyor or manual roller conveyor systems—can significantly enhance your workflow. These systems combine the best of simplicity and functionality, helping businesses stay efficient in a competitive environment.