In the dynamic realm of warehouse management, automation has emerged as a game-changer, revolutionizing traditional practices and propelling productivity to unprecedented heights. Let's delve into the various facets of warehouse automation and how they contribute to enhanced efficiency and cost savings.

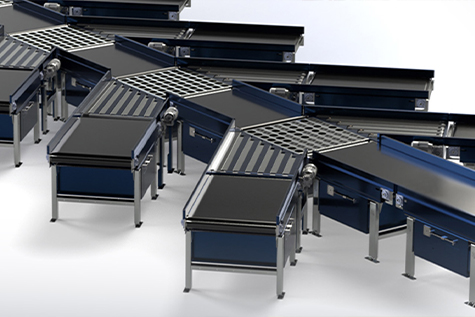

Types of Warehouse Automation

Warehouse automation encompasses a diverse array of technologies and systems aimed at streamlining operations. From simple conveyor systems to sophisticated robotic solutions, the spectrum of automation is vast and continually evolving.

Stacker Cranes

Among the most iconic symbols of warehouse automation are stacker cranes. These towering machines efficiently navigate aisles, swiftly retrieving or storing goods with precision. Their ability to access vertical storage locations maximizes warehouse space utilization, making them indispensable in modern logistics hubs.

Improved Productivity

At the heart of warehouse automation lies the promise of improved productivity. By leveraging automated solutions, businesses can significantly enhance throughput and operational efficiency. Tasks that once required hours of laborious manual effort can now be accomplished in a fraction of the time, empowering organizations to meet increasing demand with ease.

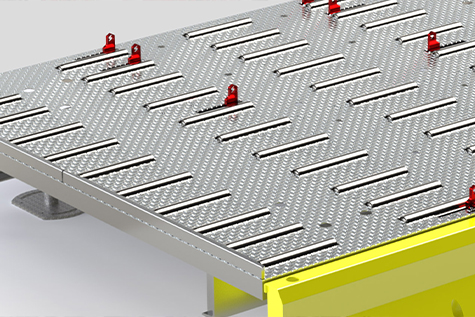

Warehouse Space Optimization

Effective space utilization is a paramount concern in warehouse management. Automation solutions, such as vertical storage systems and compact robotic modules, enable businesses to make the most of limited space. By stacking goods vertically and utilizing every inch of available area, warehouses can accommodate larger inventory volumes without expanding their physical footprint.

Cost Savings through Automation

One of the most compelling advantages of warehouse automation is its ability to reduce labor costs. By automating repetitive tasks like picking, packing, and palletizing, businesses can trim their workforce requirements and allocate resources more strategically. This not only lowers operational expenses but also minimizes the risk of errors associated with manual labor, mitigating potential losses due to human error.

Warehouse Automation Systems

From sophisticated software solutions to hardware components, warehouse automation systems encompass a myriad of technologies working in tandem to optimize operations. Advanced software platforms orchestrate the seamless interaction between various automated devices, ensuring synchronized movement and efficient utilization of resources.

Store and Retrieve with Precision

The hallmark of a well-automated warehouse lies in its ability to store and retrieve goods with precision and speed. Whether it's a high-speed robotic arm plucking items from shelves or an automated guided vehicle navigating through aisles, every action is meticulously orchestrated to minimize downtime and maximize throughput.

Mitigating Human Error

Human error poses a significant challenge in warehouse operations, potentially leading to delays, inaccuracies, and costly mistakes. Automation serves as a bulwark against such errors, relying on consistent algorithms and precise machinery to execute tasks flawlessly. By minimizing reliance on manual labor, businesses can safeguard against the pitfalls of human fallibility, ensuring reliable and consistent performance.

In conclusion, warehouse automation represents a paradigm shift in the realm of logistics, offering unparalleled efficiency, accuracy, and cost savings. By embracing automated solutions tailored to their specific needs, businesses can unlock new levels of productivity and competitiveness in an increasingly demanding marketplace.